RAS STUDIO HOMES

Crafting Spaces, Shaping Dreams

Production Process

v

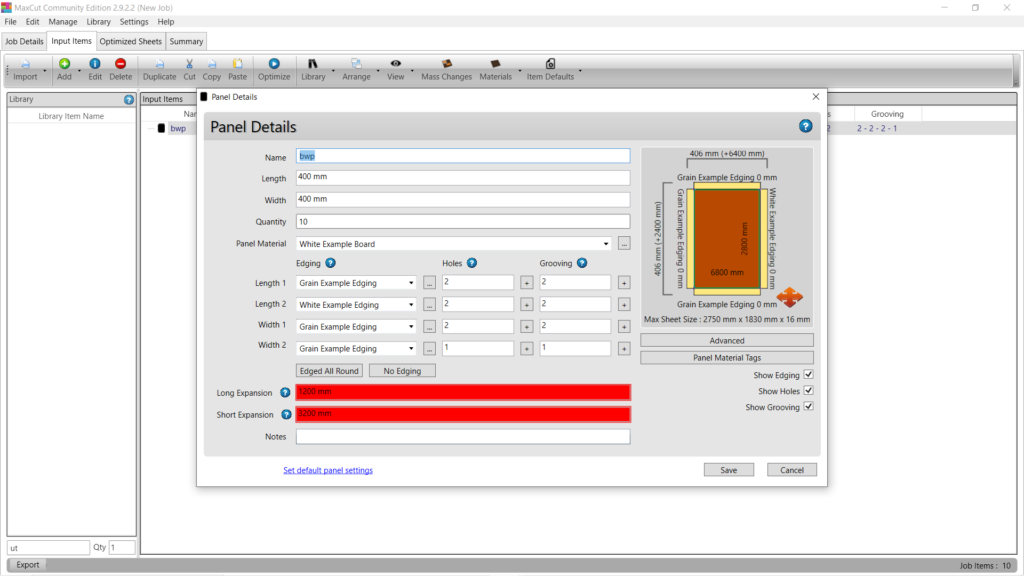

Panel Details

entry into software:

Production team

looks at designs and carefully comes up with all the parts of each

furniture with its exact size and finishes.

This part list is

then entered into a production planning software.

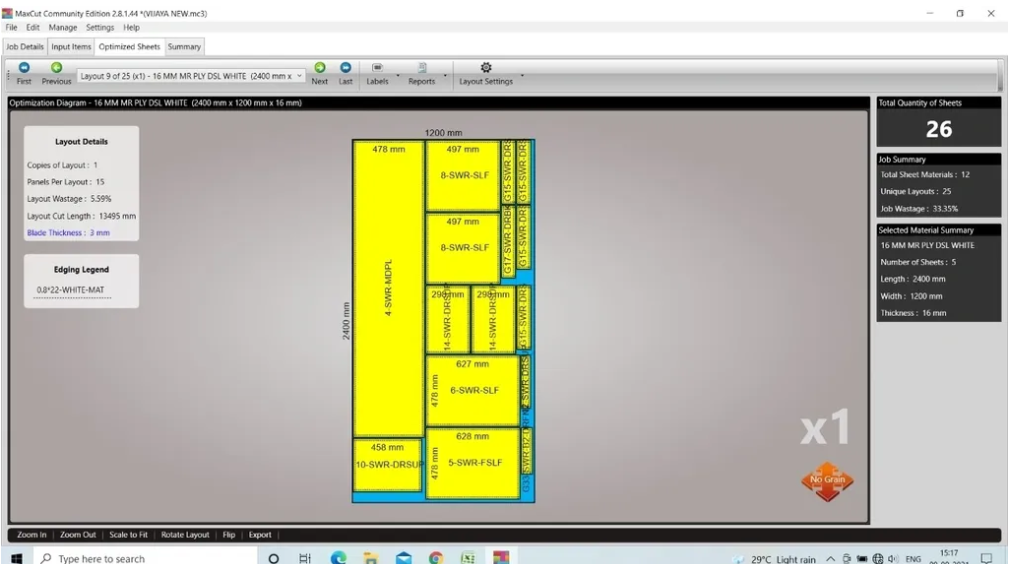

v Layout details for production:

Production planning software segregates all

parts as per material finishes and then maps similar ones onto plywood sheets.

This reduces wastage as well as minimizes errors by factory staff.

We get a bunch of layouts like this.

This document is

passed to factory for production.

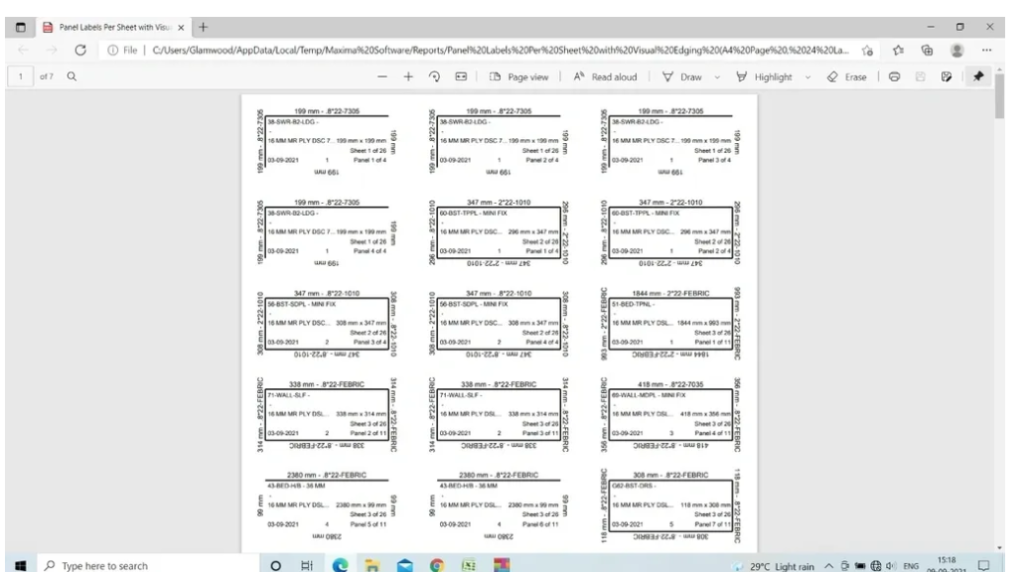

v Fine details for Quality check:

Production team also prints these stickers

and passes to factory to paste on each piece/part of furniture.

This helps in Quality check, correction & segregation

As per layout

shared, Procurement team orders the plywood , laminates and other raw material

and moved the project to factory team.

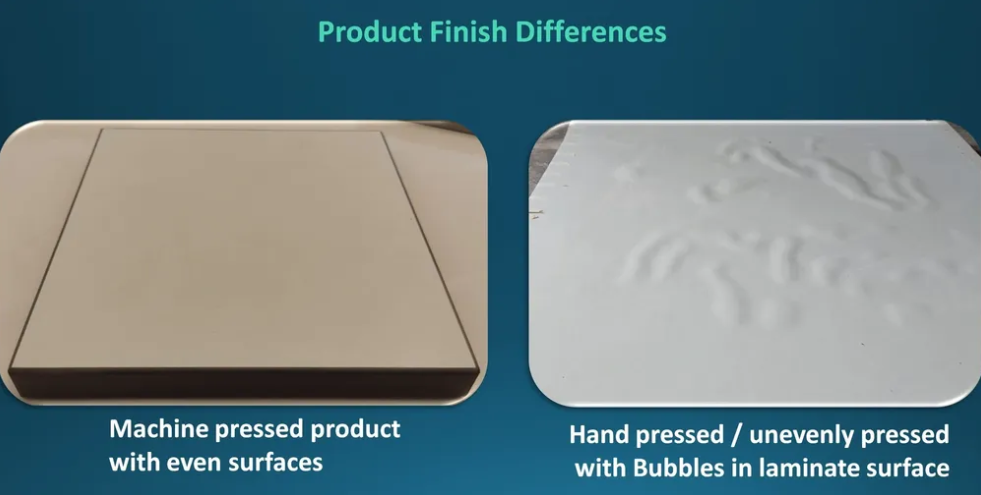

v Production - Pasting of

laminates:

4 cylinder hydraulic press with 100 ton

pressure

First all the laminates are pasted on the full plywood (unlike carpenters make the wardrobe first and then cat & paste the laminates).

You can see the difference in quality between hand pressed vs RAS STUDIO HOMES automated 100 ton 4 cylinder machine pressed.

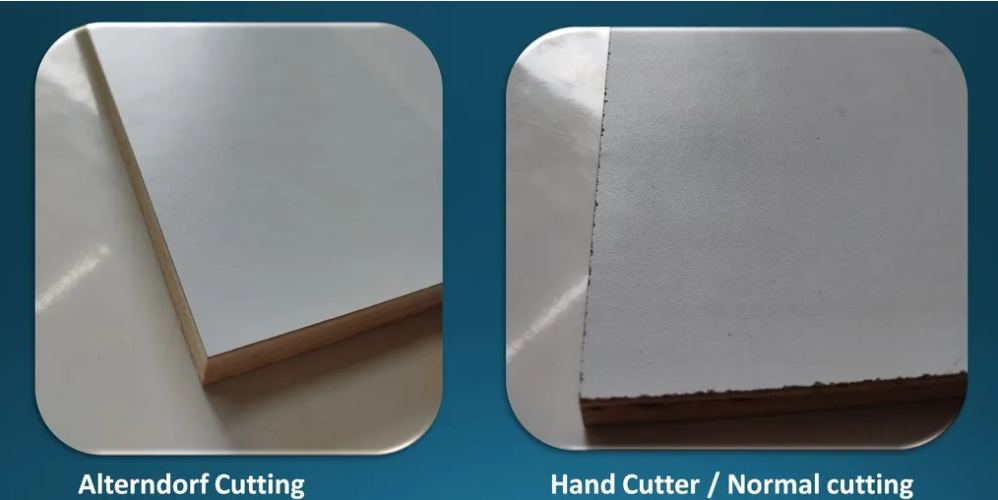

v Production-Cutting:

German Cutting machine with diamond edge

blade, cutting precision of 0.1mm

Each ply is cut as per the layout received

from the production team and sticker is pasted on each piece.

From this point onwards all the cut pieces are

moved to racks and stay on racks till they are packed so that no piece gets

damaged or scratched.

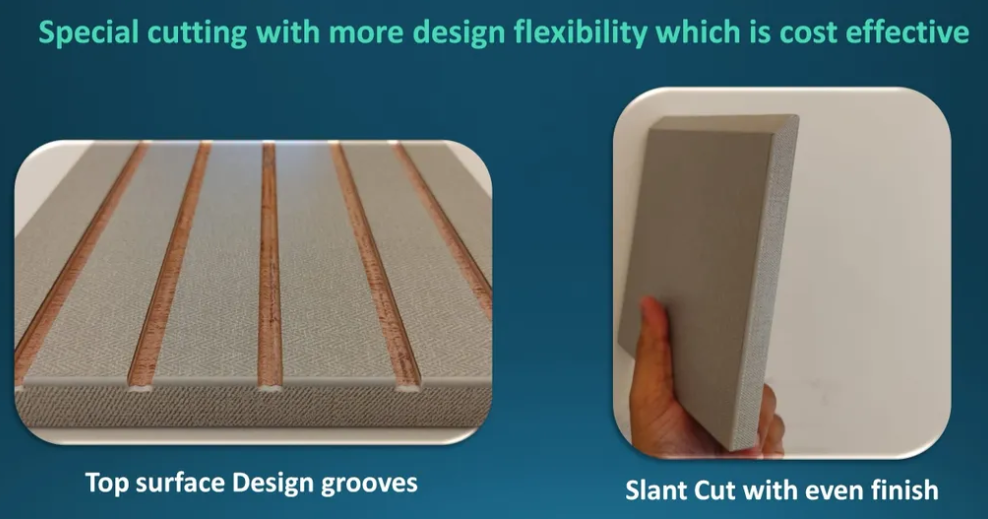

This cutting machine also allows to give

special kind of finishes which other cheaper machines are not able to do so.

Example, slant cut is required for handle less doors or drawer faces. Hand cut slant pieces are very

hard to provide with such finishing.

v Production – Edgebanding:

Biesse (Italian) edge banding machine - fully

automated

Edge banding machine adds edge band

(PVC tape of color matching with the laminate) to all 4 edges of the piece of

furniture.

Machine does corner rounding ( even rounding

of top/bottom corners of corners), edge scraping, glue scraping,

polishing

You

can see the difference in finishing. Also as the outer material is PVC, it is

soft and as it is rounded from every possible place it does not hurt even if

someone bangs into accidently.

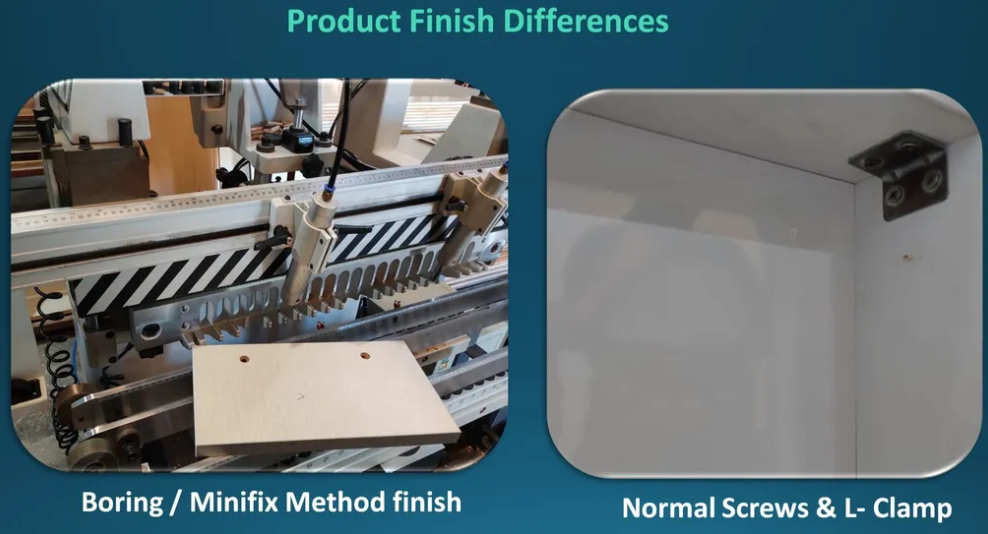

v Production – Boring :

This machine is must for true modular work.

Minifix holes are done on each part of every box so that carpenter can fixed

easily at the site.

This not only reduced manual mistakes but also adds to the looks as minifix parts are mostly

hidden. Lastly unit can be easily opened anytime and moved to a new place.

Multiboring machines helps in avoiding use screws and clamps.

v Assembly and Quality check:

Each unit is

assembled loosely at factory to check any issues in production. Any issues

found are fixed right there and to avoid any issues / delays in work

after material is shipped to the site.

v Packing and Dispatch:

Furniture parts are packed unit wise with

clear labels on each box for easy installtion at site.

Each box is first

a packed with shrink wrap so that it remains tightly packed and then with

cardbaord layer on top and box corners are given an extra layer of foam to

avoid damage during transport.

Copyright © 2024 RAS STUDIO HOMES. All rights reserved.